During the construction process, a site’s soil is often unable to sustain the weight of an intended structure. Piling, often made of steel, is the foundational structure that solidifies a deep foundation to support structural integrity from underground and above ground.

Pile Driving Definition

To construct a secure foundation, a pile driver pounds piling material into the ground until the piling rests on sturdy bedrock. A useful way to understand the definition of pile driving is likening the process to using a hammer (pile driver) to force a nail (pile) through a wall (ground) into a stud (bedrock).

A nail stuck in drywall alone will not bear much weight, but if the nail sticks into the solid stud beneath the wall’s surface, it will help the nail support weight. Similarly, a foundation set in loose or unstable soil would cause a structure to collapse under its own weight. But placing a foundation on hard, unmoving bedrock makes the structure stable.

How Pile Driving Works

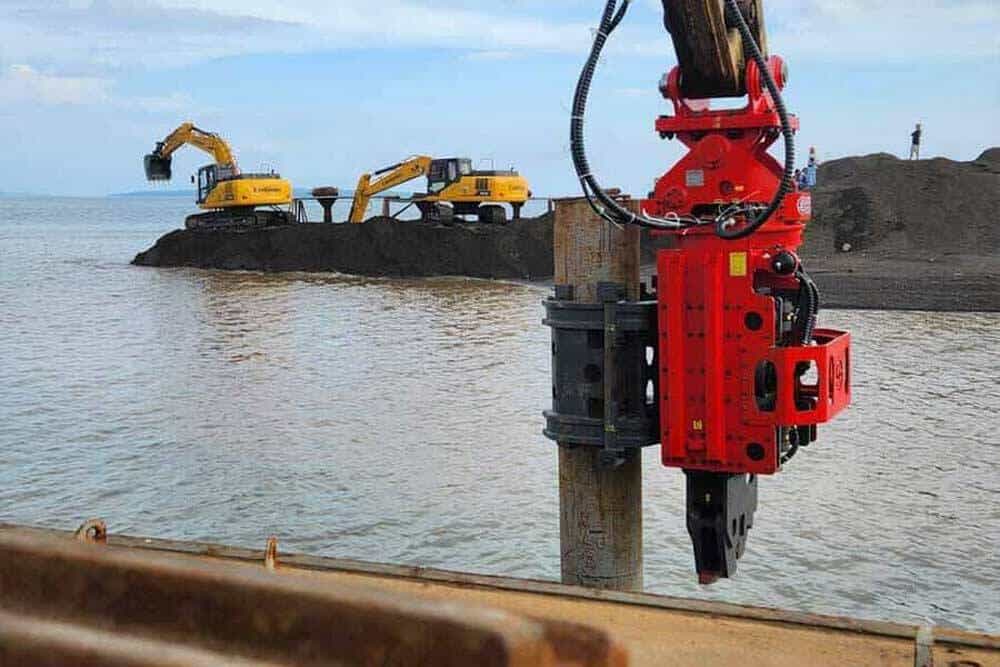

Pile drivers are machines that drive piles into the ground to form structural foundations. It works by winching and hanging a heavy weight over a pile while surrounded by a guidance frame. Then, the weight would be released to fall down and hammer the pile into the earth below. Now there are more advanced and efficient types of pile drivers, including diesel hammer, hydraulic hammer, and vibratory hammers. Manufacturers commonly design diesel, hydraulic, and vibratory pile drivers to mount onto other construction equipment like cranes and excavators. That helps maneuver pile drivers and piles into place.

How Diesel Pile Drivers Work

Despite being disruptively loud and less environmentally friendly, diesel pile drivers are popular due to their simplicity and cost effectiveness.

In diesel pile drivers, a piston compresses the air and fuel inside a cylinder on an impact block, creating an explosion. The resulting force pushes the pile beneath down into the ground and moves the piston back up in the housing to reset before coming down again.

How Hydraulic Pile Drivers Work

Other types of pile drivers produce considerable noise, and the vibrations they generate can interfere with structures in the vicinity. Newer hydraulic pile drivers minimize the effects of vibration and are quieter, operating at about 70 decibels. These work by replacing the compressed air and fuel inside cylinders with hydraulic fluid.

How Vibratory Pile Drivers Work

Vibratory pile drivers are ideal for smaller spaces, due to their distinct design with less need for vertical clearance. They circumvent horizontal vibrations by using counter-rotating eccentric weights that are powered hydraulically. This concentrates vertical vibrations to press the pile underneath down into the ground. Different hammers can attach to vibration pile drivers which vibrate between 1,200 and 2,400 times per minute.

The Use of Pile Driving In Commercial Construction

The ground on a construction site needs to be stable enough to withstand the entire weight of the structure on top of it. When the topsoil provides insufficient support for a foundation, pile drivers hammer piling down through the soil and against the bedrock. The type of soil dictates how much force a pile driver needs to use to correctly put piling where it needs to go. Contractors and engineers dictate attachments like conical points to weld onto the end of a pile and help secure the above-ground weight of a structure.

Pile driving has a number of benefits in construction. The structural integrity and safety of a structure depends most significantly on an adequate foundation. Driving steel piling for a deep foundation is a fast process that minimizes land disruption and environmental invasiveness. The practice of pile driving steel in particular has the eco-friendly benefit of using a highly recyclable material. There are a variety of steel piling types with corresponding applications.

Driving H-Piles in Construction

Shaped like the letter H, H-piles are versatile for use under friction and end bearing, and are compatible with most standard pile drivers. They hold up well under tension, performing well to resist pull. These piles distribute weight widely to uphold the structural burden of large structures like skyscrapers and bridges.

Driving Pipe Piles in Construction

Cylindrical pipe piles provide 30% more surface friction than H-piles, which helps hold them in place within the soil. Pipe piles facilitate more even weight distribution. With the capacity to fill with concrete and reinforce using rebar, pipe piles can hold up to higher underground pressure.

Driving Sheet Piling in Construction

Z-shaped steel sheet piling, also called Z-piles, come in long interlocking sections to form a continuous structural wall. They are stiff, resistant to bending, and make strong retaining structures for soil and water.

Types of Commercial Pile Drivers

For any demolition or excavation project, there are diesel, hydraulic, and vibratory pile drives, and some are available with crane and excavator mounting capabilities:

- Excavator mounted vibratory and hydraulic pile drivers attach to excavator pump systems and power packs for efficient operation in the smallest size applications

- Side grip vibratory pile drivers to fit larger 8-50 ton excavators and drive pile up to 15 m in depth through hard ground

- Crane mounted vibratory pile drivers- for long sheet or steel tube pile 25 m or longer -and separate hydraulic power packs for use in bridge and sea port projects

- Internationally advanced level performance diesel hammer pile drivers with two-stroke engines, simple maintenance and operation, a large variety of piling material and applications

- New environmentally-friendly multi-function silent piler with full hydraulic drive and automatic control, minimal vibration and noise, and small size for easy field transfer

IAI offers a range of pile drivers at discount prices in a selection of sizes, weights, frequencies, and centrifugal force. The selection caters to your specific job requirements and budget. IAI ensures the lowest rates with the price match guarantee program. All products are world-class quality with free shipping in the U.S. and the security of a three-year warranty.

Shop custom solutions, call for helpful expertise, and get the best prices available. Purchase World-Class Pile Drivers With IAI.

Recent Comments